There are several ways to bond metal based on the application. The following are the common ways to bond metal together.

Adhesive

The most simple way to bond metal. The main material is a resin so it is not resistant to environmental changes after bonding.

Fusion Bonding

This dissolves the base material during the bonding process so it causes appearance or dimensional changes after bonding.

Wax Bonding

Using capillary effect of wetability surface to penetrate welding flux to bonded interface.And after removing the oxide on the bonded surface, the wax material creates an alloy layer to hold it together.Bond strength and corrosiveness is dependent on the wax material, but the bond strength is weaker than solid phase bonding.

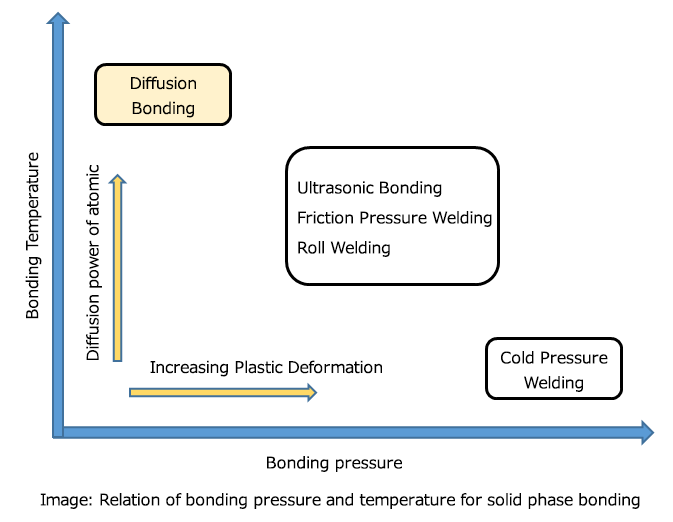

Solid Phase Bonding

The bonding processes which do not use any adhesive or wax.Apply heat and pressure to the surface of the materials and join them together at the atomic level.This method allows you to get the highest bonded strength.

Using adhesive, wax or solder bonding is the most common technique; however you may experience weaker bonded strength, no long term reliability, separation at high temperatures,small gaps between the layers and the material will be difficult to clean.Overall, we recommend diffusion bonding (solid phase bonding) to join materials together.

Below are various processes for solid phase bonding which do not use adhesives.The following are the advantages of Diffusion Bonding.

Also no burr or dross which is an advantage of photo etching working well together with diffusion bonding.This aligns with our core value of photo etching with high accuracy and innovative technology.With this technique we can offer three dimensional products with a high aspect ratio which are difficult to create from other cutting or machining processes.

The following materials are the major materials we can offer for diffusion bonding.Please contact us for more details on other materials.

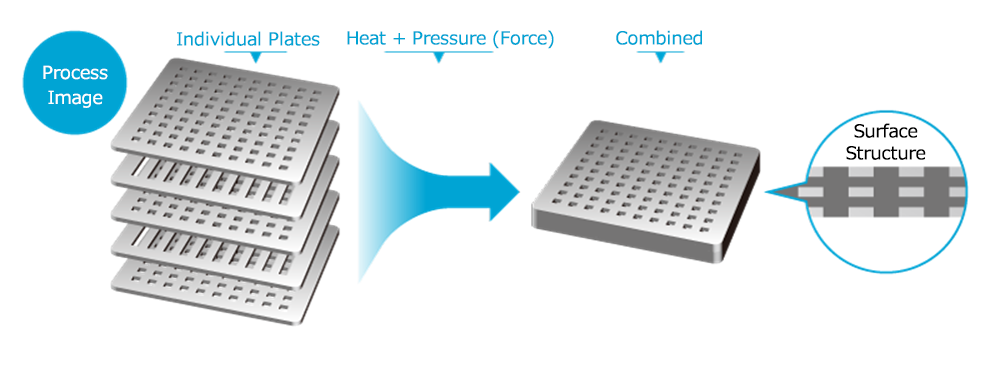

We take the following steps during diffusion bonding.

(1) Create the pattern → (2) Stack and align each plate → (3) Bond in the vacuum sealed furnace → (4) Remove from furnace, finished!

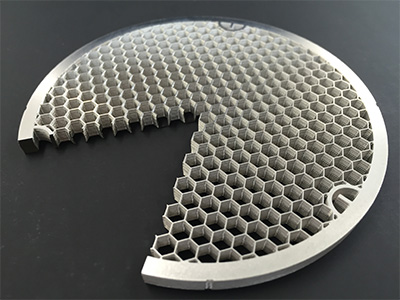

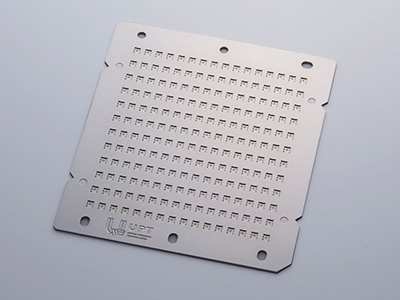

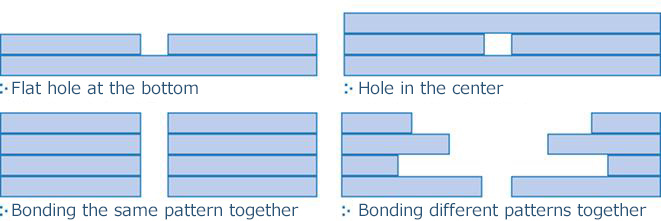

In order to get the required design or shape, we select the suitable plate thicknesses and apply various patterns with photo etching.The following pictures show the various patterns of structures that are possible.

Diffusion bonding can be used for various applications, the following are some major applications.